EN 2243-3 Climbing Drum Peel Test at honeycombs

The climbing drum peel test according E 2243-3 is used to evaluate the Separating force / adhesion of the top layer of a composite system (honeycomb core with a cover layer). This combination has an extreme stiffness depending on the high-quality bonding of both parts. The adhesive force is determined by means of special peeling tool. Due to the special design of this test tool, the connection is not peeled apart by shearing force, but is nearly orthogonally peeled.

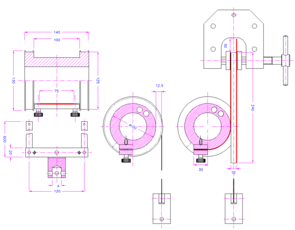

The drum peeling tool can easily be adapted to a GALDABINI universal testing machine. In addition, a simple clamping head is required, on which the opposite side of the cover is clamped and pulled at a speed of 25 mm. The graph of the force increases steadily in the experiment until a repetitive spontaneous partial detachment takes place. The cover layer gradually loosens. In order to prevent a falsification of the adhesive force by start-up behaviour / a fall at the end, the beginning and the end regions are not taken into evaluation. An adhesion mean value is calculated from the mean part of the gross force. This represents the adhesive force together with the drum weight and the top layer stiffness. In a second driving path, an average force is again determined to receive the stiffness of layer. The net peel resistance (net adhesion force) is determined by subtracting the ascertained drum weight and ascertained cover layer stiffness. In the drum peeling tool, a counter-weight prevents a distortion of force due to eccentricity.

With a GALDABINI testing machine you may

- download the method and extract the ZIP

- copy the complete folder to data folder

- load the method to preferred methods ("Search")

- mount climbing drum peel fixture

teach in: start position | type of load cell | overload limit to 5 kN (protection tool)

Application note EN 2243-3 Climbing Drum Peel Test | ||

Target of test | Measuring the gluing of the layer of honeycomb (carbon fibre) | |

Testing machine | Universal testing machine class 1 - Load cell ~ 1 kN or bigger (max. 5 kN) | |

Testing tools | climbing Drum Peel fixture | |

Specimen preparation | Sawing, milling | |

standard | EN 2243-3 (equivalent ASTM D 1781) | |

Tool dimension | drum-Ø 100 | driver rolls-Ø 125 | width for specimen 100 | |

Testing speed | 25 mm/minute Auf Ab Auf Ab (4 phases) | |

Specimen geometry | Specimen width 75 mm, specimen length 300 mm incl. 2 times clamping 25 mm | |

Results | description: average value of typically oscillating forces | unit |

Total force | Layer stiffness, drum weight, net pealing force | N |

Drum weight | Incl. Layer stiffness and drum weight | N |

Layer stiffness | Difference of drum winding force / unwinding force | N |