Tensile specimens marking apparatus

to measure the elongation after the tensile test

Marking system for measuring elongation manually

marking within seconds

With these marking devices tensile specimens can be marked in the simplest way so that the elongation at break can then be measured manually. The mark is carved and not beaten. It therefore has no influence on the test result for most materials. Round specimens (tubes, rods) and flat specimens (square tubes, flat specimens made of hot strip, flat specimens made of thin sheet) as well as reinforcing steel can be easily and quickly marked. Depending on the marking apparatus selected, pitches of 10 or 5 mm are possible. The sample mounting is very easy and is done with two clamping fixtures. All graduations are applied with only two crank turns. Thanks to the spring-loaded marking needles / scribing needles, markings are very even with little wear on the tips. The sub-machine is placed on a table and achieves good stability due to its own weight.

To determine the elongation at break, the broken specimen is positioned in a support prism (special accessory) so that the axes of the two fragments form a straight line. Then the extension (Lu) is measured with a caliper gauge.

- If the purchase of a costly long-stroke extensometer does not seem advisable due to low sample volumes, other methods must be used to determine the exact elongation at break.

- For critical applications, it is also sometimes necessary to measure the elongation at break using conventional methods.

- Furthermore, manual measurement of elongation at break according to various standards is mandatory (ASTM / NADCAP / BS / API).

And last but not least, it must be made clear some specimens that have no naking in the L0 / Lc range (tubes, parallel strips, reinforcing steel, square tubes, bar material) tend to crack off-centre. If the specimen is extended outside the sensors (outside the cutting distance Le), no exact results with respect to the A-values are possible and the test with a long-range extensometer must be discarded.

The marking device (dividing device) manufactured in Germany is efficient to operate and applies the desired sample marking within seconds:

- Inserting the sample rod

- Close clamps

- Turn crank 2 x ... done

This marking device is available in different versions and pitche with split tension clamps for reinforcing steel crosses

- MA200-5 Marking device with a marking length of 200 mm in increments of 5 mm

- MA200-10 Marking device with a marking length of 200 mm in increments of 10 mm

- MA300-5 Marking device with a marking length of 300 mm in increments of 5 mm

- MA300-10 Marking device with a marking length of 300 mm in increments of 10 mm

- tailored to your application: on request

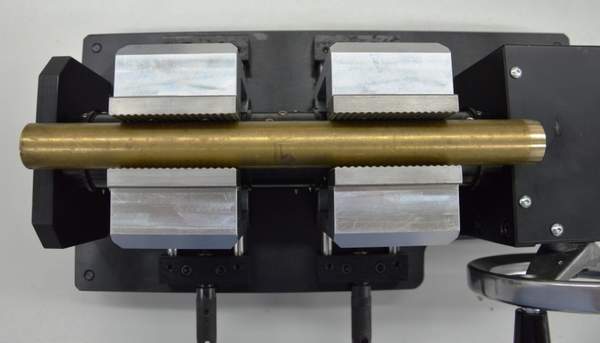

Marking device MA300-10 with clamped reinforcing steel

Marking device MA300-10 with clamped aluminium tube

[Translate to English:] Markierapparat MA300-10 mit gespannter Flachzugprobe Warmband

Customers | |

MA200-10 | |

ArcelorMittal Méditerranée | F-13776 Fos Sur Mer |

MA300-5 | |

Badische Drahtwerke GmbH | D-77694 Kehl |

LCC Testsystems (Vertrieb RU) | RU-153027 Ivanova City |

ArcelorMittal Hochfeld GmbH | D-47107 Duisburg |

LCC Testsystems (Vertrieb RU) | RU-153027 Ivanova City |

|

|

MA300-5 + Wechselwalze 10 | |

LCC Testsystems (Vertrieb RU) | RU-153027 Ivanova City |

|

|

MA300-10 | |

B. Lütkenhaus GmbH | D-48249 Dülmen |

CRH Concrete A/S | DK-6650 Broerup Dänemark |

Max Frank Pressig GmbH | D-96332 Pressig |

![[Translate to English:] Markierapparat MA300-10 mit Flachzugprobe [Translate to English:] Markierapparat MA300-10 mit Flachzugprobe](https://static.schuetz-licht.com/__p14r__/9/4/csm_MA300_fuer_Flachzugproben_e975d8fa24.jpg)