high potential energy required

ISO 148: Only 80% kinetic energy can be used

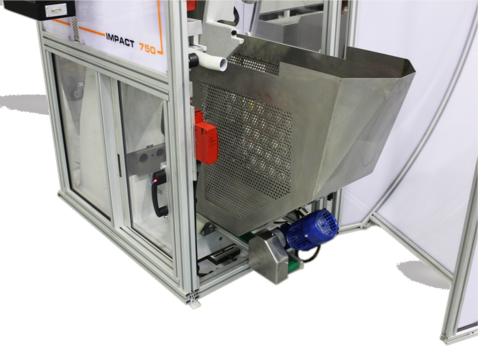

Different materials - especially modern materials with high toughness - increasingly require the purchase of pendulum impact testers with higher potential impact energy. A robust pendulum impact tester with a high dead weight and a heavy foundation is required to perform a notched bar impact test. GALDABINI offers pendulum impact testers with five different energy potentials for testing a wide range of metals.

When choosing a pendulum impact tester, please note that according to the ISO 148 standard, only up to 80 % of the potential energy are allowed to be used. Even a single use of the entire energy (100% of the potential kinetic impact energy) can lead to machine damage. Therefore (according to the standard) the pendulum impact tester must be recalibrate after such an overloading. Please choose your equipment with care and take into account both your business planning and the fact that the materials are constantly being developed. Until about 1990, the equipment typically included a pendulum hammer with an impact energy of 150 Joule. With additional weights the potential energy could be increased to 300 Joule. Today (for the steel / stainless steel sector) almost exclusively pendulum impact testers with an energy of 450 Joule or higher are purchased. It is no longer common for a pendulum impact tester to have a second measuring range by means of additional weights. Here the standard says: Even low ductile materials can be tested on the pendulum impact tester if the results of the indirect calibration (reference samples) are within the tolerance (e.g. 17 J. for IMPACT 450).

GALDABINI IMPACT | usable energy 80% | typical material | Industry / application |

150 Joule | 120 Joule | aluminum cast, gray cast, Spheroidal graphite iron | foundries, aluminum foundries, aluminum plants |

300 Joule | 240 Joule | steel, steel cast, sheet metal | steel / sheet metal industry, education university / schools |

450 Joule | 360 Joule | tough steels, stainless steel | standard equipment |

600 Joule | 480 Joule | stainless steel | Stainless steel production, Stainless steel processing |

750 Joule | 600 Joule | stainless steel | Stainless steel production, stainless steel processing |

robust technique and precise electronic

operation real simple

The operating principle of a pendulum impact tester is relatively simple: A pendulum hammer strikes a notched bar impact test specimen from a defined height of fall. When hitting this, different amounts of energy are used for breaking or bending (tough materials). Depending on the energy consumed, the pendulum hammer continues to swing at different heights on the opposite side of the abutments. Traditionally, this maximum point of swinging through was determined by drag pointer. Today this angle is determined by means of an angle encoder and electronics. Depending on the height of the swing through (the maximum angle of climb is measured) the energy consumed can be calculated from the difference between kinetic energy and residual energy after the impact. The construction of a pendulum impact tester may seem simple. However, the following requirements should not be underestimated:

- precision of electronics

- Rigidity of the frame

- Solidity of the pendulum hammer and abutments

- Control system

- Protective housing with interlock

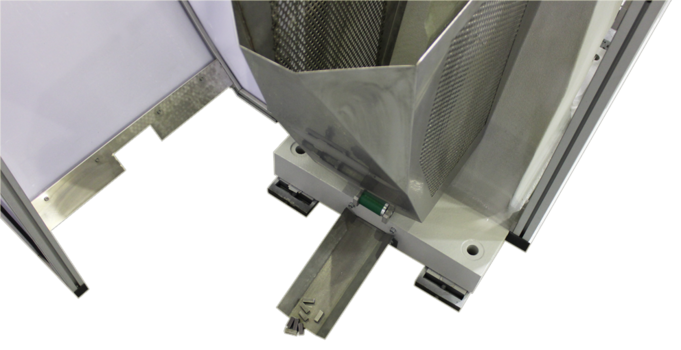

- Centering device

- optional sample chute and sample removal by conveyor belt

In addition to the most precise determination of the results by means of a high-resolution angle of rotation encoder and counter electronics, the robustness of the loaded assemblies plays a decisive role. From our work as a DAkkS calibration laboratory, we know of many cases where pendulum impact testers do not meet the calibration requirements: Often the measured values of the indirect test by means of reference samples are outside the tolerances according to ISO 148, but it is precisely here that the machines differ: The GALDABINI pendulum impact testers have a C-shaped frame and C-shaped hammer. The abutments are mounted on the portal of the machine. Compared to other machines (with U-shaped pendulum hammers), the abutments of this design are much less sensitive to vibration and elastic deformation of the machine (abutments of U-shaped pendulum hammers are basically fixed to the base plate).

In recent years, it has become increasingly apparent that pendulum impact testers need to be replaced as the further development of materials leads to ever greater material toughness, thus necessitating equipment with higher working capacity. In addition, the increased safety requirements in industry as well as at universities and vocational schools are taken into account: Today, this testing equipment must have a complete protective housing and it must be made impossible for the careless operator to open it while the pendulum hammer is moving. Therefore a motorized hammer lifting and a motorized centering device are almost mandatory. All these requirements for quality and performance are met and exceeded by a GALDABINI pendulum impact tester.

Quality of pendulum impact tester

GALDABINI has supplied a large number of IMPACT pendulum impact testers worldwide. It is standard (due to the design with C-pendulum hammer) that the DAkkS calibrations are fulfilled without any complaints and that the devices work without damage and failure - for years. Although the wear parts (hammer fin and abutment inserts) are made of powder metallurgical steels - here wear is inevitable. For this reason, especially for high toughness materials, where the specimens do not break (but are pulled along the abutments), a replacement fin and exchangeable abutment inserts should be purchased when the pendulum impact tester is first purchased (only applies to 450 joules or more | pendulum impact testers with 300 joules usually work for years without replacement of wear parts due to the lower impact strength of the materials).

Options and additional equipment

In addition to the basic unit, further options can be offered. These increase the comfort or allow testing with cooled samples

- cooling baths

- Loading tongs

- Sample chute in funnel shape

- Conveyor belt for transporting the broken samples

- Evaluation software for the display and archiving of the tests

- instrumented pendulum impact testers with applied hammer fin, high-performance electronics and special evaluation software

- Notch broaching machine for the rational notch insertion into a notched bar impact test specimen

- services: DAkkS- / ASTM / NIST - calibration

- Reference samples for indirect calibration according to ISO / ASTM / NIST